Metrology in Rochester, Indiana

Flenar Manufacturing has a firm grasp on traditional and modern digital measurement techniques, and we utilize both to ensure adherence to dimensional tolerances during production and final inspection. Among our metrology services are comparator inspection, hard gauging, and CMM inspection.

What is Metrology?

Metrology is the scientific study of measurement. When referring to machining, metrology is a catch-all term used to describe quality assurance methods that keep machinery calibrated prior to production; these methods also ensure proper measurement of the parts produced during a run.

Before production on a part begins, metrological equipment is used to calibrate any machines or tools that will be used during the process. If the piece being machined has been optimized for manufacturability, its tolerances will be measured with meteorological equipment to ensure that any minor differences in component size will not affect the fit, form, or function of the piece. Metrology is once again used once production is completed to guarantee the produced components meet customer expectations.

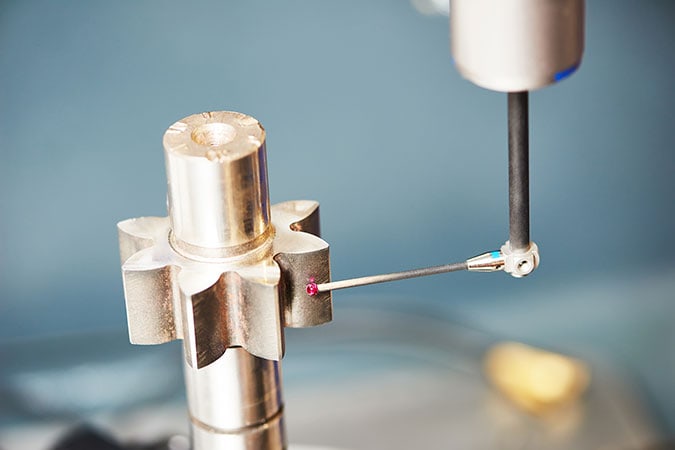

CMM Machines for Metrology

A CMM (coordinate measuring machine) is a piece of equipment that ensures parts are produced with the specific dimensions and characteristics prescribed by customers. These CMM machines utilize a three-axis system that aids in four different kinds of measurement: dimension, profile, angle, and depth. Flenar uses a quality management system together with CMM’s to guarantee dimensional tolerances are met in both production and final inspection.

CMM Inspection

Our CMM’s inspection process allows components for individual products to be measured and quality-checked. A CMM is capable of measuring a single point in a 3D shape, or the entire shape if necessary. Each machine utilizes three axes, each axis helping to measure the product as well as position it accurately for other machines.

There is a wide range of capabilities that a CMM can facilitate, including:

- Dimensional – The ability to measure multiple axes of an object to read its full dimensions.

- Profile – Capturing profile information and the form of both 2D and 3D objects.

- Angle – Measuring angles and orientation of two different points of an object.

- Depth – Ability to map the depth of any object with the use of two stereo images.